With the continuous increase of labor costs, more and more companies have begun to pay attention to the field of industrial automation equipment, especially non-standard automation equipment. Convenience and versatility have brought new business opportunities to the industrial manufacturing industry. my country's non-standard automation equipment has begun to emerge, but it has encountered many obstacles in the development process.

Strong demand for non-standard automation equipment

In the past, China's manufacturing boom relied on a lot of cheap labor. However, with the passage of time, with the decrease in the number of new laborers in recent years and the improvement of people's living standards, labor is no longer a cheap resource, and it has become more and more common to find a job that is difficult to find. In order to meet the needs of production, automated production has gradually been Recognized and valued by business owners. As an important part of automated production, non-standard equipment has become more and more popular in the past 10 years, and a large number of non-standard equipment manufacturers have emerged in the market.

At present, the demand for enterprises to adopt automation equipment is increasing. Due to the different specific conditions of each enterprise, the demand for non-standard automation occupies a large proportion. The expenses of non-standard equipment and machines can be budgeted in advance, such as machine depreciation, electricity, gas, daily maintenance, operator wages, etc. The productivity of a machine can be equivalent to several (less) dozens or even hundreds of people. Of course, the faster the speed, the higher the cost of the machine. The production cost of the product is greatly saved. Moreover, the quality of the products produced by the machine is more guaranteed. In China after the financial crisis, non-standard automation equipment will inevitably become more prosperous.

The non-standard automation market will grow rapidly, and the application depth of automation products will continue to increase. In this field, compared with developed countries, there is a gap of 10-20 years in the overall domestic level. New non-standard automation equipment is often mechatronics equipment, making full use of the newer achievements of information technology. The designers of some Chinese enterprises are not familiar with electronic products and dare not or will not choose them, which greatly limits the improvement of their level. However, in the past 10 years, non-standard automation has been widely used in Jiangsu, Zhejiang and Shanghai, the Pearl River Delta, and Beijing-Tianjin regions, and domestic enterprises are catching up.

Development status of non-standard automation equipment

Although the non-standard equipment industry as a whole presents an obvious upward trend, that is, the non-standard equipment market has broad space, and even some traditional industries may become a market with great potential. However, the number of non-standard enterprises in my country is large, the scale is small, the technology is backward, and the competition is homogeneous.

New non-standard automation equipment is often mechatronics equipment, making full use of the newer achievements of information technology. The designers of some Chinese enterprises are not familiar with electronic products, and they dare not or will not choose them, which greatly limits the improvement of their level. Many core technologies are not truly independent, and it is obviously difficult to reduce the cost of relying on equipment imports. At present, high-quality products are still mainly imported from abroad.

According to market logic, the growing market space can improve the technology research and development level of enterprises and expand the scale of enterprises, and provide enterprises with good development opportunities. However, the objective situation is the opposite. Domestic non-standard equipment enterprises have not stepped out of the vicious circle of low quality and low price. They are still simply imitating, and have not developed their own characteristic products and patented products, and have not accumulated more funds for business development. At present, the small workshop production of more than a dozen people is still the mainstream form of the non-standard equipment industry.

Discuss barriers to development

The formation of anything has its subjective and objective reasons, and the formation mechanism is intricate. The status quo of non-standard equipment is also the result of various elements. Although non-standard equipment is still a relatively healthy industry, the seven obstacles in front of it have increasingly affected the development of the non-standard automation equipment industry.

Non-standard equipment cannot be mass-produced, large enterprises are unwilling to do it, and small-scale enterprises can easily obtain living space.

Non-standard equipment is equipment that has no standard to follow and is tailored according to the production status of the enterprise. The equipment of company A is often only applicable to company A, and cannot be copied to company B in batch production. Usually, it takes two or three months for a piece of equipment of about 300,000 RMB to provide requirements from the customer, the non-standard equipment factory to provide the scheme design, the two parties to discuss and determine the scheme, sign the contract, produce the design drawings, process the parts, and complete the equipment assembly and acceptance. . Because the input-output ratio is too low, large-scale enterprises do not care about such trivial and long-cycle small orders. But such a project is quite attractive for small businesses with only 10 people. A small business with sales and a few mechanical engineers and a few software engineers is growing like crazy.

The market size of non-standard equipment has grown, but the pie has become bigger, and there are more people who share the pie.

In 2000, only some Taiwanese factories in the Pearl River Delta and the Yangtze River Delta were well-known for producing non-standard equipment in China, and there were about 30 factories in total. According to the statistics of relevant data, the scale of non-standard equipment in that year is estimated to be around 600 million, and these 30 companies account for about 70% of the market share. By 2012, there were more than 70 non-standard equipment factories in Chang'an, an important hardware manufacturing town in China, and there was countless small-scale non-standard equipment in the country, with an order of magnitude of more than 10,000; the market size was also estimated to grow to about 60 billion. In a simple sentence, although the market size has increased by 100 times, the number of manufacturers has increased by a thousand times. The newly added market is occupied by many small manufacturers. Failed to form a large-scale enterprise.

The threshold for non-standard equipment enterprises is low, and the quality of personnel varies.

Why are there so many non-standard manufacturers in the market? The reason is that the initial investment cost of the non-standard equipment factory is low, and the entire investment is estimated to be around 300,000. With a few grinders, a few milling machines, and a house of several hundred square meters, a dozen or so people can operate a non-standard equipment company. Usually, the non-standard equipment factory entrepreneurial model is a joint investment of two or three shareholders, one shareholder is responsible for sales, one shareholder is responsible for technology, and one shareholder is responsible for after-sales, without the intervention of large capital and large enterprises. This situation has caused the non-standard equipment industry to be relatively closed, the industry cannot be reshuffled, good money cannot drive out bad money, and companies are mixed.

Pursue the doctrine of borrowing, and innovate and develop less.

Domestic non-standard enterprises rarely have new inventions, new creations, and new applications. An important purpose for domestic enterprises to visit and participate in exhibitions at home and abroad is to discover new applications, new processes, and new technologies. This approach is very positive in many ways. He shortened the equipment gap between my country and developed countries, and improved the level of industrial modernization and agricultural modernization, thereby reducing the labor intensity of the masses. However, there is no doubt that this kind of plagiarism under the banner of reference has seriously reduced the enthusiasm of enterprises to develop new technologies and new applications; over time, it has affected the technical capabilities of my country's automation equipment industry, making the core always in the hands of European and American companies. It is a very sad thing to pollute the environment, sell physical strength, and demolish and build houses to develop the economy. For long-term development, we must attach great importance to the protection of intellectual property rights, so that enterprises can obtain long-term and stable benefits from research and development. The non-standard equipment industry especially needs to protect intellectual property rights.

Enterprises' requirements for automation are still relatively elementary, which restricts the development of the non-standard automation industry to a higher level.

Under the pressure of a shortage of human resources, manufacturing enterprises have chosen automation. However, automation can be roughly divided into three stages from the perspective of saving human resources: semi-automation, full automation, and integration of automation and informatization. Based on cost considerations, many companies choose semi-automated equipment, and the slightly complicated processes are still completed manually. This semi-automatic product can be completed by a person who has a good understanding of mechatronics. All designs can be completed independently. A large number of such low-level automation requirements restrict the development of non-standard industries to a higher level.

The industry is loose and there is no organizational advantage.

There is no industry association for non-standard equipment. As the saying goes, crying children have milk to eat. Without industry associations, it would be difficult for the government to hear the voices of non-standard industries, and we would not get any preferential policies, at least in terms of taxation. The various manufacturers are inseparable from each other. Non-standard equipment companies are more vigilant, afraid that their technology will be learned by others, that their customers will be taken away by others, and that their backbone personnel will be poached by others. This lack of contact and cooperation has led to non-standard equipment increasingly falling into the quagmire of price competition. A non-standard enterprise should sell technology and solutions. However, many non-standard enterprises are now discussing material costs and management costs with customers. We should think that without technology, non-standard equipment is just a pile of scrap iron, so we should elaborate more on how much our non-standard equipment can save customers and improve how much benefit, what we get is a reasonable return for our mental work.

The advantages of large-scale enterprises are not obvious.

Although small enterprises are the mainstream of non-standard industries, there are also some medium-sized non-standard enterprises with more than 100 employees. The annual output value of these medium-sized non-standard enterprises is at the level of tens of millions. However, due to management problems, designers and equipment personnel have not shown sufficient sense of responsibility, resulting in the unsatisfactory product quality performance of some medium-sized non-standard enterprises. Over time, many manufacturers have turned to small non-standard enterprises to buy relatively cheap non-standard products.

At present, there are a large number of non-standard automation and mechanization enterprises in my country, but the scale is small, the technology is backward, and the competition is homogeneous. How to participate in the competition in this industry has become a challenge! There are difficulties to have opportunities. Facing a good market prospect and development space, it is also a particularly attractive place for this industry. Enterprises that have gone through the early stage of survival will surely usher in the rapid development of the industry.

What equipment needed for luncheon meat canning?

What equipment needed for luncheon meat canning?

What equipment needed for ice cup production plant?

What equipment needed for ice cup production plant?

How to select a right filling machine?

How to select a right filling machine?

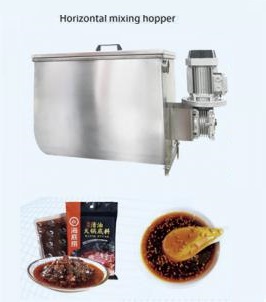

How to select a right buffering hopper for filling machine?

How to select a right buffering hopper for filling machine?