Brief introduction of this hot air popcorn processing and packing line:

1. The heating way of the popcorn-making machine is hot air circulating to ensure that the pop rate is higher than 95%.

2. It is equipped with a sifting system to automatically filtrate non-popped and un-sized popcorn.

3. Parts touches with popcorn all are stainless steel.

4. Also can be equipped with a Screw conveyor to add corn kernels to achieve fully automatic operation.

5. Specialized equipment for caramelizing and sugar caramel coating, easy to operate.

6. Specialized mixing caramel equipment to ensure coating evenly.

7. After coating sugar, it also can equip with a separation cooling machine to cool, separate popcorn then ensure pack timely.

8. PLC control box, easy to operate.

9. Different types of packaging equipment can be connected to the processing line to pack the popcorn in bags, cups, jar, etc.

The footprint of the complete line:

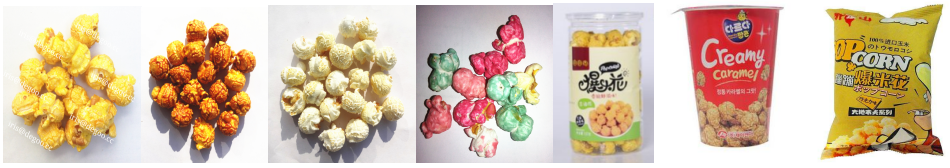

Sample products:

Successful cases: